In today’s rapidly evolving manufacturing world, traditional dispensing processes are reaching their limitations. As products become smaller, thinner, and more complex—especially in electronics, semiconductor packaging, and precision medical components—manual or conventional CNC dispensing methods often struggle to keep up with the demand for ultra-high precision and consistency.

Typical challenges include product tolerance variations, manual placement errors, misalignment of Mark points resulting in glue offset, over-dispensing, under-dispensing, and low production efficiency.

To address these growing challenges, CCD vision positioning dispensing machines leverage high-resolution imaging, intelligent algorithms, and precision motion control to achieve micron-level automated dispensing accuracy.

This article provides a comprehensive explanation of CCD vision dispensing machines—from definitions and principles to applications, performance metrics, industry comparisons, and selection guidelines.

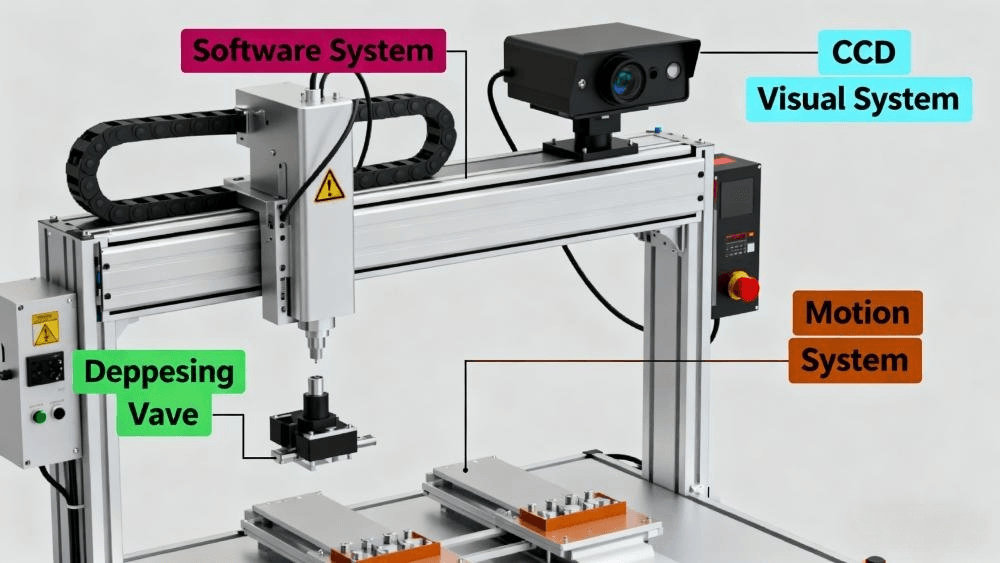

A CCD vision positioning dispensing machine integrates high-resolution industrial CCD cameras, precision optical lenses, intelligent image processing algorithms, high-performance motion platforms, and advanced dispensing valves. Instead of relying on manual alignment, it uses vision to recognize product positions and guide the dispensing head to the exact target location with microscopic accuracy.

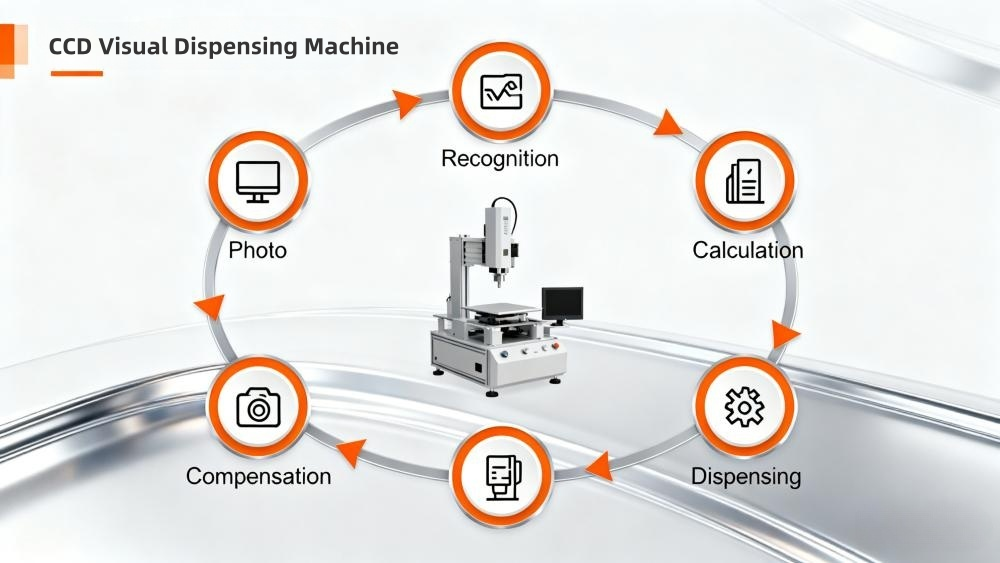

The CCD vision detection workflow includes:

1. Image Acquisition: The camera captures product features such as Mark points, contours, holes, and edges using controlled lighting.

2. Image Processing: The system performs enhancement, noise reduction, and binarization for clear feature extraction.

3. Feature & Coordinate Extraction: The vision software calculates center coordinates and rotation angles.

4. Coordinate Conversion: Image coordinates are converted into mechanical coordinates through calibration.

5. Path Compensation: The system automatically adjusts dispensing paths based on X, Y, and θ deviations.

6. Precision Execution: The dispensing head completes accurate dot, line, arc, or sealing operations.

Feeding & Positioning: Products enter via conveyors or fixtures.

Vision Calibration: Ensures camera and motion system alignment.

Initial Positioning: Camera scans products and identifies Mark points.

Deviation Calculation: System computes X, Y, and θ displacement.

Path Compensation: Controller adjusts dispensing coordinates.

Precision Dispensing: The compensated path guarantees high accuracy.

Optional Secondary Inspection: Post-dispensing vision check ensures glue quality.

CCD vision compensates for fixture tolerance, product variance, and manual errors, achieving up to ±0.01 mm repeatability.

Even if parts shift on the conveyor, the system realigns automatically.

Before dispensing: detects wrong parts, missing components, or orientation errors.

After dispensing: detects glue overflow, insufficient glue, displacement, or broken glue lines.

CCD dispensing reduces dependence on skilled operators and enhances 24/7 automation.

Positioning Accuracy: ±0.01 mm after calibration.

Repeatability: ±0.01 mm for high-end models.

Dispensing Accuracy: Typically ±0.02–0.05 mm.

Mainstream accuracy: ±0.02–0.05 mm; high-end: within ±0.01 mm.

| Feature | CCD Vision Dispensing Machine | CNC/Gantry Dispensing Machine | Manual Dispensing |

|---|---|---|---|

| Positioning | Automatic vision recognition & compensation | Preset coordinates | Manual alignment |

| Tolerance Adaptability | High | Medium | Low |

| Precision | ±0.01–0.05 mm | Depends on fixture | Unstable |

| Flexibility | High | Medium | Low |

| Efficiency | High | Medium | Very low |

| Initial Cost | High | Medium | Low |

| Long-term Cost | Low | Medium | High |

Q1: Does the CCD vision dispensing machine require stable lighting?

Yes, but built-in light sources minimize environmental interference.

Q2: Can it work without Mark points?

Yes. Contour matching and edge detection can be used.

Q3: Is programming difficult?

Modern systems provide intuitive teaching-based interfaces.

Q4: What is the price range?

Generally from USD 5,000 to USD 30,000+ based on configuration.

Q5: Can it handle 3D curved surfaces?

Yes, using 3D vision or Z-axis following technology.

CCD vision dispensing machines are transforming modern manufacturing with high precision, intelligence, and automation. They significantly improve product quality, reduce labor dependence, and increase production efficiency.

Established in 2011, Shenzhen ZCX Technology Co., Ltd. is a leading Chinese manufacturer specializing in glue dispensing machines and silicone extrusion solutions. With strong R&D capabilities, comprehensive technical support, and a global customer base, ZCX is committed to providing reliable, precise, and innovative automation equipment for various industries.

Contact us anytime for custom solutions or free sample testing.